Speed and efficient logistics define a company’s competitiveness, yet many organizations still rely on legacy systems, putting themselves at increasing risk. Built on outdated technologies, these systems hinder adaptability and are ticking time bombs, set to become incompatible with modern digital platforms soon.

According to McKinsey, more than 70 percent of companies still rely on spreadsheets as their primary tool for supply chain planning—an alarming indicator of resistance to digital transformation, whether due to high implementation costs or a lack of specialized talent. The consequences are clear: greater vulnerability to downtime. Every minute a logistics system fails results in delays, revenue losses, reputational harm, and a breakdown in trust from customers and business partners alike.

So, let’s explore why modernizing your logistics software is no longer optional and how custom tools can be the key to positioning your company as a market leader.

Challenges when modernizing your supply chain

The Fourth Industrial Revolution's technologies, such as AI, ML, and IoT, have transformed how industries operate, making processes more efficient and responsive. At the same time, these advances have reshaped customer expectations. Today’s clients demand greater transparency, competitive pricing, brands that align with their lifestyles, and more personalized, varied service options.

While the benefits of modernizing the supply chain are undeniable, the process comes with significant obstacles. Time and resources are among the top concerns that make executives hesitate. Implementing logistics software solutions can streamline this process, but the complexity of integrating new technologies into existing systems remains a daunting task.

For example, industries with highly complex supply chains may require up to six years and investments between $62.5 million and $125 million to implement a new system fully. Even companies with less complex operations can expect a two to three-year transformation process, costing anywhere from $5 million to $17 million.

Another major challenge is selecting the right IT vendor to lead the project. Businesses often evaluate two to eight or more organizations, considering vendors’ capabilities, how the new system will integrate with existing applications, and the long-term operational costs. This makes finding the right team a time-consuming and high-stakes decision.

Benefits of custom logistics software solutions

One of the most strategic advantages of using custom software tools is that they’re built specifically to meet your business’s operational needs. While off-the-shelf systems can work for some companies, they often leave gaps that force teams to juggle multiple tools and platforms, resulting in workflow disruptions and communication breakdowns. On the other hand, custom logistics management software offers several key benefits that directly impact performance and scalability.

Higher efficiency: Tailored tools allow businesses to centralize logistics operations within a single platform, eliminating the need to switch between systems. This streamlines processes, reduces manual tasks, and improves cross-department communication.

Improved visibility and tracking: Custom software makes 24/7 tracking far more effective, whether you're monitoring shipments, vehicles, or inventory. Enhanced visibility enables faster decision-making, greater transparency, and proactive issue resolution.

Advanced analytics and reporting: A well-structured, advanced data architecture makes it easier to collect, visualize, and analyze data in real-time. Instead of relying on spreadsheets, business owners gain access to dynamic dashboards and automated reports that support better forecasting and strategic planning.

Another significant advantage lies in how custom systems handle data itself. Legacy systems often create fragmented and disorganized data environments, making cleaning, integration, and analysis extremely complex. A tailored platform with proper data governance enables smoother access, better storage, and a foundation strong enough to integrate AI and ML capabilities, paving the way for more intelligent, predictive, and efficient logistics.

Current and future trends

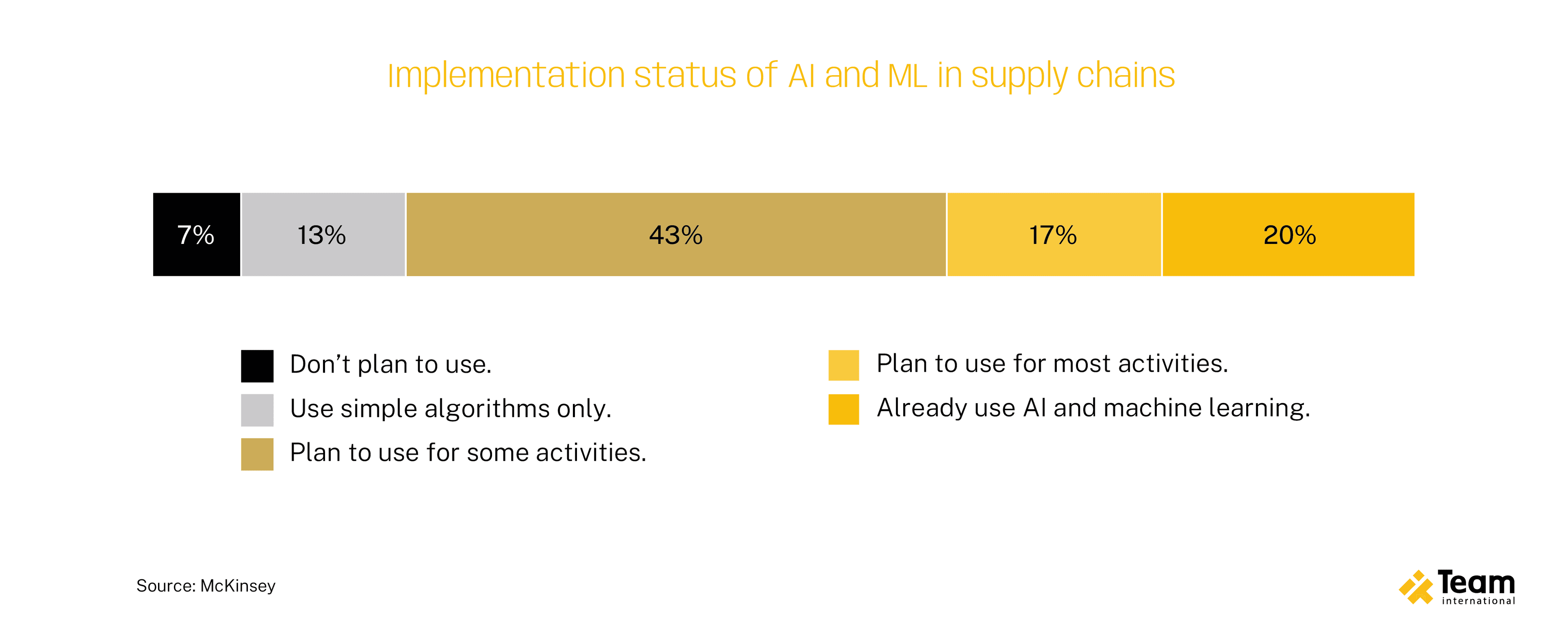

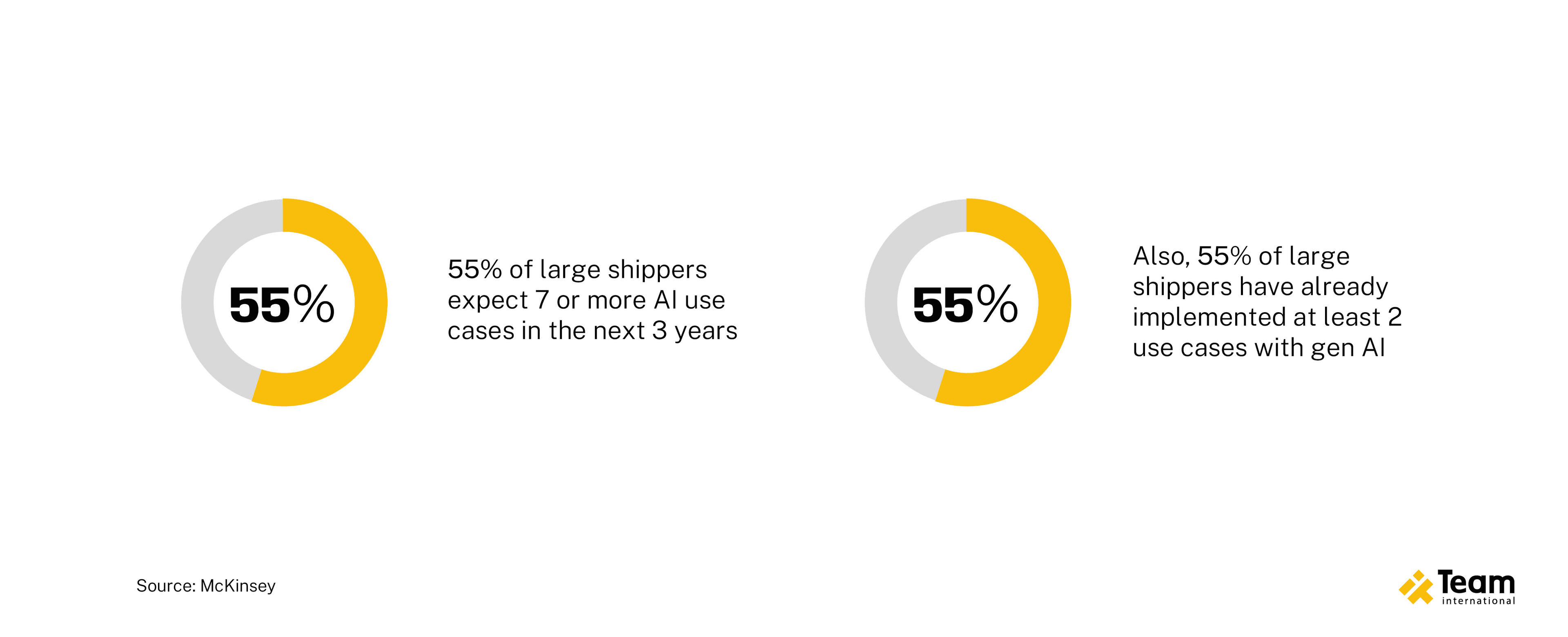

The logistics industry is undergoing a drastic transformation, and technology is set to play a central role in reshaping how companies manage operations now and in the years ahead. Those with complex supply chains already leverage AI-powered tools to streamline planning, increase responsiveness, and gain competitive advantages.

McKinsey states that larger enterprises, with annual revenues exceeding $500 million, are leading the way in adopting emerging technologies. These companies actively implement AI across multiple areas, including task automation, demand forecasting, inventory optimization, and predictive asset maintenance. Their scale and resources allow them to invest in advanced tools that drive efficiency and reduce operational risks.

In contrast, small to mid-sized businesses with revenues under $500 million tend to lag in adoption. This gap is often due to limited budgets, a more conservative investment approach, or the lack of in-house technical expertise. However, this also presents a significant opportunity: as technology becomes more accessible and customizable, even smaller businesses can begin to harness AI to optimize their supply chain processes.

The future points toward increased use of integrated, AI-enhanced systems that automate tasks and provide real-time insights and decision-making support. Technologies like machine learning, IoT, and digital twins will become more commonplace, creating supply chains that are more efficient, adaptive, and resilient to disruption.

Implementing custom logistics software for your business

Implementing a new logistics system is a large-scale initiative that requires strategic planning and thoughtful execution. While each company’s journey will vary based on its size, complexity, and goals, we can generally divide the process into three key phases.

1. Phase one: Assessing your current logistics processes

Evaluating your current logistics operations is essential before diving into vendor selection or technical development. You have to identify pain points, inefficiencies, and areas for improvement. This phase should also outline what an ideal system would look like, one that fully leverages modern technologies and is tailored to your operational goals. Engaging stakeholders from different departments ensures a more complete and realistic understanding of your needs.

2. Phase two: Choosing the right logistics software development partner

Once requirements are precise, the next step is identifying and evaluating potential technology partners for logistics software development services. Create a checklist that separates critical must-have features from desirable nice-to-haves. Ask shortlisted vendors for product demos, ideally using scenarios based on the challenges identified in phase one. This will give you insights into how each vendor approaches problem-solving and how well their tools align with your specific use cases.

3. Phase three: Development and implementation

During this phase, it’s crucial to prioritize features essential to business operations and establish a phased development timeline. Regardless of which vendor you choose, it should develop custom logistics solutions in iterative cycles with continuous testing and user feedback. Once the system is ready, we recommend launching it in parallel with your existing system to ensure smooth integration and validate performance in real-world conditions before full deployment.

Afterthoughts

At TEAM, we understand how challenging it can be to undertake a project as complex as modernizing your legacy systems and developing custom logistics software solutions tailored to your business. According to Gartner’s survey, over 80 percent of companies have attempted to transform their logistics operations in the past five years—yet 76 percent of those initiatives failed.

While these numbers may seem discouraging to investors and stakeholders, they highlight a critical truth: transformation isn’t optional—it’s essential for your long-term growth and competitiveness. Embracing change unlocks numerous benefits, including increased efficiency, greater transparency, and systems that align more closely with your business’s needs. More importantly, it opens the door to optimizing existing workflows and building a more resilient supply chain with significantly reduced downtime.

Modernization isn’t just about adopting new technology. It’s about enabling your business to operate smarter, faster, and more effectively.